The Of Aluminum Castings Company

Table of ContentsIndicators on Aluminum Castings Company You Should KnowThe Definitive Guide to Aluminum Castings CompanyThe smart Trick of Aluminum Castings Company That Nobody is Talking AboutExcitement About Aluminum Castings CompanyThe Greatest Guide To Aluminum Castings Company9 Easy Facts About Aluminum Castings Company ExplainedGet This Report about Aluminum Castings Company

The enhancement of silicon can improve the fluidity of the alloy and lower thermal shrinking, making the spreading much easier to load the mold and lowering the generation of pores. Generally utilized in car engine parts, hydraulic components, cylinder heads, etc. Aluminum copper alloy (Al-Cu) Contains light weight aluminum and copper, often with percentages of nickel and manganese included.Blowing up light weight aluminum components These optional coatings give versatility and functionality, making it possible for makers to tailor the appearance and performance of light weight aluminum parts to particular requirements and applications. Of course, the actors light weight aluminum itself can also be done without surface therapy.

Aluminum Castings Company for Beginners

Each instance showcases the versatility and functionality of actors aluminum in daily life. This short article offers information regarding actors aluminum, from the spreading procedure to comparisons with cast iron and wrought light weight aluminum, its advantages, typical resources, optional surfaces, and different cast aluminum manufacturing items. Whether you are discovering prototyping options for a brand-new item or wish to place an existing product into production, please call us and we have professional designers to help you.

Rumored Buzz on Aluminum Castings Company

- Cast light weight aluminum items might have inner problems such as pores and additions, which impact their toughness and efficiency.

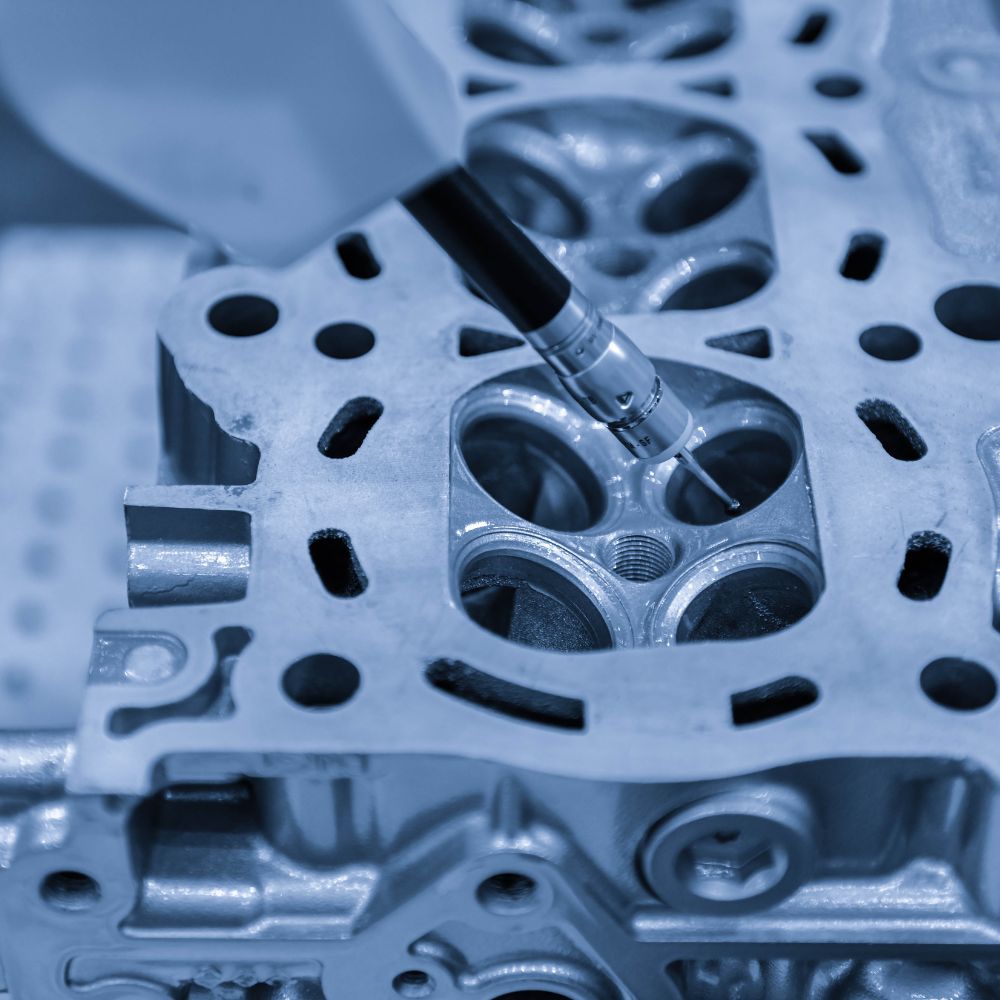

(Image source: Internet) Aluminum spreading is a technique for producing high resistance and premium quality parts by pouring molten aluminum right into a specifically made and accuracy engineered die, mold and mildew, or form. It is a reliable process for the manufacturing of complicated, elaborate, thorough components that exactly match the requirements of the original style.

Aluminum Castings Company Fundamentals Explained

This specific procedure is among a number of techniques utilized to produce light weight aluminum castings, each of which is utilized for the development of certain kinds of parts - Aluminum Castings Company. A variant in the spreading procedures is the kind of mold, which can be permanently constructed from steel or momentarily made of a non-metallic product

In order to go over the light weight aluminum spreading procedure, it is necessary to examine each of the different unique methods and how they are used given that there isn't just one procedure. There are makers that specialize in one or several techniques, several producers provide clients a choice as to which procedure they would like.

Aluminum Castings Company - The Facts

From the smallest electrical component considering much less than a gram to transmission cases and clutch real estates for vehicles, casting produces each part specifically to the requirements of the layout, flawlessly with little demand for completing. The introduction of aluminum casting has offered designers the opportunity to make any kind of type of arrangement with the assurance that the component will perform as much as expectations.

Computerization has actually enhanced the pressure to be capable of on schedule shipments to satisfy consumer demands (https://disqus.com/by/alumnmcstngs/about/). As the need for raised efficiency and performance expands, aluminum die casting has been even more than efficient in conference and surpassing what has come to be called for. Parts, components, and work surfaces are produced at a high price of rate that is quicker than any type of other kind of alloy

Getting My Aluminum Castings Company To Work

Aluminum items are light-weight yet have the strength of steel. This variable contributes to their endurance and life span, an essential factor for 21st Century items. (Picture source: Web) Though light weight aluminum spreadings are exceptionally solid and light-weight, they have an extremely favorable appearance and visual value. There are a number of uses for aluminum spreading that do not require them to be seen or have a pleasurable look.

Every sector is looking for means and approaches to reduce costs but generate premium quality products. The reduced cost of the light weight aluminum casting process is a major factor in why companies are picking it for product advancement. Much of the price financial savings is due to the rate of manufacturing and the removal of the additional hints need to complete completed products.

When light weight aluminum castings are revealed to the air, their surface ends up being oxidized, which is a quality of the steel. This one variable is the reason that aluminum spreadings have durability and dependability. This improved life time offers users with better value (https://medium.com/@kelliphillips61401/mastering-sand-molding-with-aluminum-castings-company-a1e9edce0c8f). * Source:.

The 4-Minute Rule for Aluminum Castings Company

This short article contains all the information you need to understand about light weight aluminum casting (Sand Foundry). You will learn more about subjects such as: What is light weight aluminum casting? Aluminum casting refines Aluminum alloys Advantages of light weight aluminum spreading And far more Light weight aluminum casting is the process of putting liquified light weight aluminum into specially crafted passes away, molds, or kinds to manufacture parts with high accuracy and superior high quality

It is worth noting that the first development, CNC machining, and tooling of these long lasting molds is labor-intensive and requires upfront financial investment, which should be considered when assessing general manufacturing expenses versus various other casting methods such as sand casting or low-pressure spreading. In spite of this, the lasting benefitssuch as reduced per-unit price, phenomenal component uniformity, and much shorter lead timesoften exceed the first arrangement costs for mid- to large-scale light weight aluminum casting jobs.

The mold and mildew is diligently crafted to match the precise geometric form and casting resistance required for the partoften split right into two or more fifty percents (occasionally called die halves). Throughout metal spreading, these fifty percents are secured firmly with each other to avoid the intro of air, impurities, or incorporations, ensuring a thick and defect-free structure.